The Difference Between Knotless vs. Knotted Netting

Wondering what the differences between knotless vs knotted netting are? There are numerous, including applications, benefits, strengths, and durability, all of which we’ve delved into in this comparison.

As the UK's leading netting supplier, we manufacture and distribute both knotless and knotted netting across various industries, and we have different recommendations for each based on the use case.

To help you understand more about the differences between knotless and knotted netting, we've broken things down in this guide. Whether you’re trying to determine which will be the best for your project, or you’re simply curious about the way each type is created, you’ll find all the answers here…

Key Takeaways

-

Knotted netting is strong, durable, and reliable, making it ideal for heavy-duty uses like sports, cargo, and safety applications.

-

Knotless netting offers a smoother, lighter, and more flexible design that reduces abrasion, making it perfect for bird control, playgrounds, and agriculture.

-

The main difference lies in construction and performance: knots add strength but increase weight and friction, while knotless designs remove weak points and provide a cleaner appearance.

- Choosing between the two depends on your project’s needs — whether you prioritise maximum strength and cost-effectiveness or flexibility, aesthetics, and gentler handling.

Download Our Netting Catalogues Today

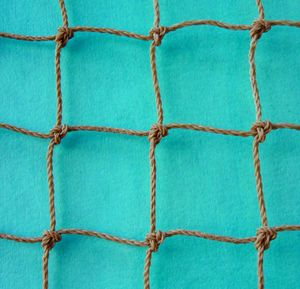

What is Knotted Netting?

Knotted netting is constructed by intertwining individual strands of material to form secure knots at each point where the strands intersect.

This traditional method of net fabrication creates a robust and reliable structure, ensuring the knots stay firmly in place under tension.

Typically made from durable materials such as polypropylene, nylon, or polyethene, knotted netting is designed to resist wear and tear, making it suitable for heavy-duty applications.

The knotted intersections provide added strength and stability, which is why this type of netting is often preferred for uses where high tensile strength and durability are required, such as in sports, fishing, and industrial settings.

Knotted Netting Benefits

-

Versatility: Knotted netting can be used in a wide range of applications, such as bird control, pest management, garden maintenance, tennis nets, cricket nets, and cargo climbing nets.

-

Durability: The knotted design enhances the netting's resilience, allowing it to withstand heavy loads, harsh weather conditions, and prolonged use without deteriorating.

-

High Tensile Strength: Thanks to its knotted construction, this type of netting provides exceptional tension resistance, making it ideal for demanding situations.

-

Customisability: Knotted netting can be tailored in terms of material, mesh size, and strength to suit specific applications, ensuring optimal performance for each unique requirement.

- Cost-Effectiveness: The longevity and strength of knotted netting reduce the need for frequent replacements, making it an economical option for long-term use.

Need Help Choosing the Right Netting for Your Project? Find Out More

What is Knotless Netting?

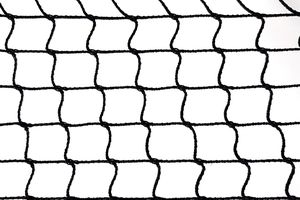

Knotless netting is a specialised type of netting that is manufactured without traditional knots, offering a smoother and more uniform structure compared to knotted alternatives.

View Our Multi-Purpose Knotless Netting

Instead of knotting the intersections of the netting fibres, the threads are fused or woven in a continuous manner, resulting in a seamless and durable construction.

This method of construction enhances the strength and integrity of the netting, as there are no knots to slip or weaken over time.

Knotless netting is often crafted from high-quality materials such as polyethene or nylon, making it highly resistant to wear, abrasion, and environmental factors.

Its innovative design also provides a softer and more aesthetically pleasing appearance, which can be advantageous for applications such as sports nets, aquaculture, and decorative uses.

Knotless Netting Benefits

-

Enhanced Durability: Knotless netting resists wear and tear effectively, making it highly suitable for prolonged use in harsh environments.

-

Superior Strength: Without knots to weaken its structure, this type of netting offers greater tensile strength and reliability.

-

Reduction of Friction Damage: The smooth construction minimises friction, reducing the likelihood of damage to delicate materials or objects in contact with the net.

-

Improved Aesthetic Appeal: Its seamless design lends a clean, professional look, making it particularly desirable for decorative or public-facing applications.

-

Lightweight but Robust: Despite being sturdy, knotless netting remains lightweight, which facilitates easy installation and handling.

-

Environmental Resistance: High-quality materials like polyethene or nylon ensure resistance to UV rays, moisture, and other environmental factors, prolonging the product’s lifespan.

-

Ideal for Aquaculture: The absence of knots helps prevent abrasion on fish, ensuring better welfare in aquaculture setups.

- Versatile Usage: Its attributes make it adaptable for a wide variety of applications, including sports equipment, agriculture, and even architectural use.

Difference Between Knotless & Knotted Netting: A Direct Comparison

When deciding on the type of netting that's going to suit your project best, it's important to know the key differences between the two front-runners.

We've created a simple table to directly compare knotless and knotted netting so you can be more informed when purchasing mesh.

|

Feature |

Knotted Netting |

Knotless Netting |

|---|---|---|

|

Durability & Strength |

Knots provide strength and durability by absorbing and distributing force, though they can become weak under extreme stress. |

Knotless netting is highly durable, with seamless construction that eliminates weak points. |

|

Weight & Flexibility |

Heavier and less flexible. |

Lightweight and flexible. Its knot-free design reduces bulk, making it easier to handle and ideal for smooth draping in various applications. |

|

Appearance & Aesthetics |

Has a more textured, traditional appearance. |

Has a smooth, uniform, and clean appearance. |

|

Abrasion |

The knots are high-friction points that can cause abrasion. |

Highly resistant to abrasion, making it a safer and gentler option for a wide range of uses. |

Explore Our Knotted & Knotless Netting

Use Cases for Knotted & Knotless Netting

While having a direct comparison of the differences between these two popular types of netting construction, it's not much use if you're not sure what each style is best suited to in terms of use cases.

Uses for Knotted Nets

To make things a little clearer, here are some of the most common uses for knotted netting:

Sports Netting:

Knotted netting is a popular choice for sports due to its strength and durability, which are essential in high-impact settings.

The knots add extra reinforcement to the net, making it resistant to repeated forceful impacts, even with constant use. This makes it ideal for sports like football, cricket, and tennis, where the netting regularly comes into contact with balls, players, and equipment.

Its strong design also helps it keep its shape and perform well over time, providing a dependable and cost-effective option for sports facilities and schools on a budget.

Browse Our Sports Netting Range

Cargo & Transport:

Knotted netting is often chosen over knotless netting for cargo and transport applications because it's stronger and more reliable.

The knots add extra strength, making the netting better suited for holding heavy or irregular loads securely without losing its integrity. This durability makes it ideal for tough environments where safety and stability are critical.

Knotted netting also resists stretching or losing its shape under pressure, ensuring consistent performance and protecting goods during transit.

These features make knotted netting a reliable option for industries needing secure and dependable cargo solutions.

Explore Our Cargo & Load Restraint Nets

Safety & Debris Netting:

Knotted netting is a top choice for safety and debris containment thanks to its strength and reliability.

The knotted design holds up under significant force, preventing debris from falling and keeping workers or areas below safe.

The durable construction also withstands harsh conditions, such as strong winds and heavy loads, which are common safety concerns in construction sites and industrial environments.

The flexibility of this traditional netting construction makes it easy to install and adapt to different project needs, offering a versatile solution for various safety and containment applications.

At Huck Nets, we offer a safety net testing service to ensure your safety netting continues to meet industry regulation standards and can withstand the forces it’s designed for.

Search Our Safety Netting Range

Other projects that require netting that's lighter or more aesthetically pleasing will benefit from knotless netting, such as:

Bird Netting:

Knotless netting is a popular choice for bird netting because its smooth design reduces the risk of harming birds (whether you're keeping them in or out!).

Without knots, the netting has a more uniform structure that prevents birds from getting tangled or injured.

The knotless design is lightweight but strong, making it ideal for aviaries where visibility and aesthetics matter. The subtlety of the design blends into the surroundings, making it less noticeable when used on buildings to keep birds from nesting.

The polyethene material commonly used in this type of netting is durable and resistant to environmental wear and tear, providing a long-lasting, humane solution for bird netting needs.

Always ensure you're using bird netting with an appropriate mesh size for the species you're protecting against to avoid injuries and tangles. For more information, read our handy guide to bird netting safety.

Playground Netting:

Knotless netting is a great option for use in playground equipment because it's durable and has a smoother design. Unlike traditional knotted netting, the knotless surface is uniform and less abrasive, reducing the risk of scrapes and scratches for kids.

This smooth finish not only makes it safer but also more comfortable for active play.

Knotless netting is also extremely strong and resistant to wear, standing up to the constant use and outdoor conditions. The reliability of the design ensures playgrounds stay safe and secure for years to come.

To get more inspiration, read some of our playground case studies, including the Drimpton Play Area and the intriguing Leys Play Area.

Explore Playground Netting Options

Agricultural Netting:

Knotless netting is a great option for agricultural use because it’s lightweight, durable, and versatile for both home and commercial gardening.

As plant netting, it effectively protects fruits and vegetables from pests, birds, and harsh weather. Its smooth, knot-free design is gentle on delicate plants, reducing the chance of damage during setup or use.

The lightweight material makes it easy to handle and install, which is especially helpful for gardeners and farmers needing quick, reliable coverage.

Whether for small gardens or large-scale operations, knotless netting provides the strength and functionality to support healthy plants and boost yields.

Browse Our Agricultural Netting Range

Find Ideal Netting Solutions at Huck Nets

At Huck Nets, we stock an extensive range of both knotted and knotless netting solutions, suitable for a variety of applications, including industrial netting, sports netting, and bird netting.

As the UK’s leading supplier of netting, we also offer custom-made netting tailored to your exact specifications for a cost-effective, straightforward solution.

Order online today, or get in touch with our experienced sales team to discuss your specific netting requirements.

Browse Our Market-Leading Netting

FAQs

What Are the Advantages and Disadvantages of Knotless Netting?

Knotless netting offers increased durability, smoother surfaces that reduce abrasion, and less weight compared to knotted alternatives. However, it can sometimes be less rigid, making it more suitable for flexible applications rather than high-tension requirements.

What is the Difference Between Knotted and Knotless Safety Netting?

Knotted safety netting is stronger and more rigid, ideal for high-tension applications, while knotless netting is lighter, smoother, and more flexible, making it suitable for applications requiring minimal abrasion and adaptability.

What Type of Netting is Best for Bird Control?

For bird control, knotless netting is best as it is lightweight, durable, and reduces the risk of feather abrasion. It ensures effective and humane protection while being adaptable to various structures and environments.

When Should I Choose Knotted Netting?

Choose knotted netting when durability and strength are key requirements, such as for high-impact sports or areas demanding extended longevity. Its resilience makes it a reliable option for securing sports facilities and protecting players and spectators alike.

Does Knotless Netting Last Longer?

Knotless netting can last longer as it eliminates stress points caused by knots, reducing wear over time. However, its longevity depends on usage and maintenance, making it ideal for projects with lower impact requirements.